Automated Drilling Units

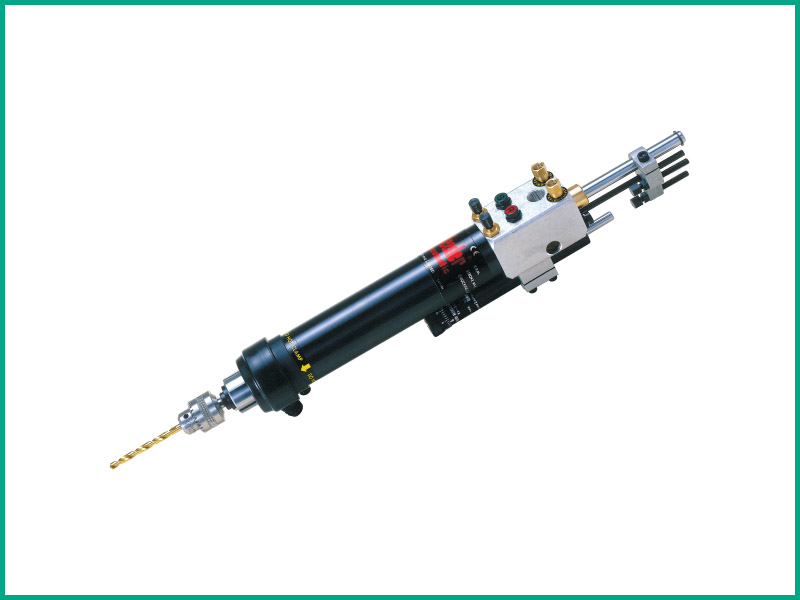

Pneumatic Type

Drilling units have the spindle speed and feed motions are operated with compressed air. These units works without any eletricity and their construction is designed for the smallest installation space.

>> Pneumatic Selfeeder SFB, SFC

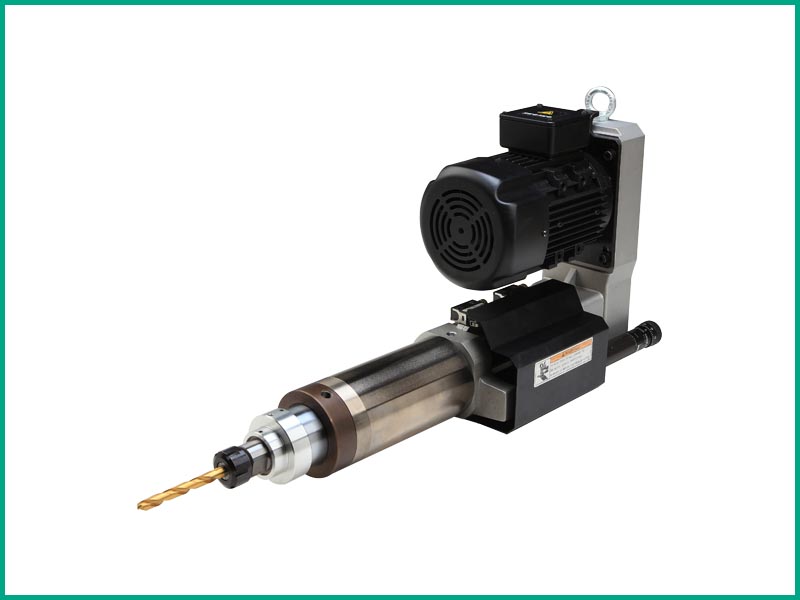

Air/Electric Type

In these models a spindle is driven by an electric induction motor in combination with a mechanical gear. Spindle forward stroke and return to its initial position is driven by a pneumatic valve.

>> Selfeeder REVO SRV 2, 3, 5

>> Selfeeder Electric SSE2 - SSE5, ES6, ES7

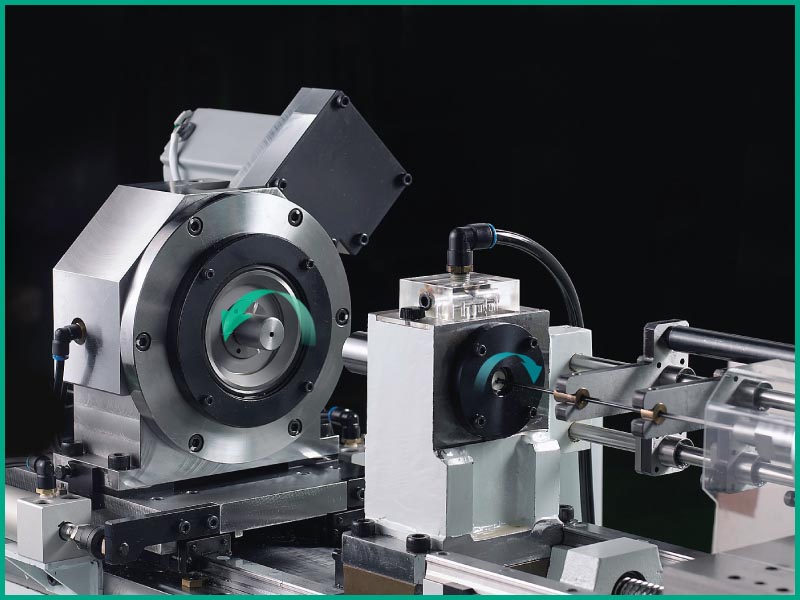

Servo Feed Type

These units have a spindle stroke controlled by a servomotor and thus significantly reduce their drilling cycle time and facilitate demanding accuracy operations as for example step boring or deburring.

>> Mechafeed REVO MSR 2,3,5

>> Selfeeder DUO

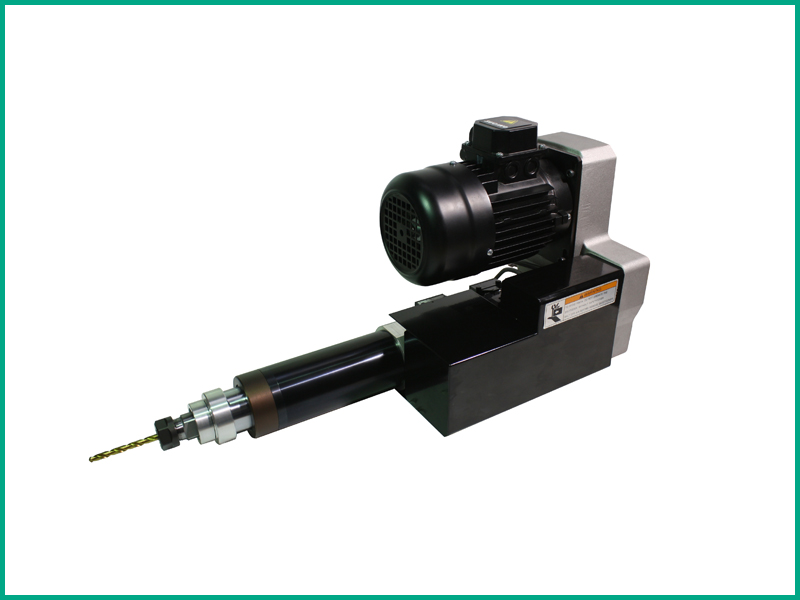

Electric drilling units

Compact, economical and rigid units suitable for boring process.

>> STX3, STX5

Automated Tapping Units

Mechanical Feed Type

SSTB and SSTC

Mechanical Feed Tapping Unit allowing effective tapping with long stroke and equipped with fast approach and fast return mechanism.

Both units have been renewed by replacing induction motor with a Permanent Magnetic (PM) motor.

>> SSTB and SSTC type

Servo Feed Type

SSTR

The Synchro Tapper REVO series are units capable of high speed precised work. The spindle rotation speed can be adjusted by the speed control box and build-in AC Servo motor improves an accuracy and reduces a total cycle time. A Synchro Tapper units with a servo driver can be easily connected to customer's universal PLC.

>> REVO SSTR 2, 3, 5, 6

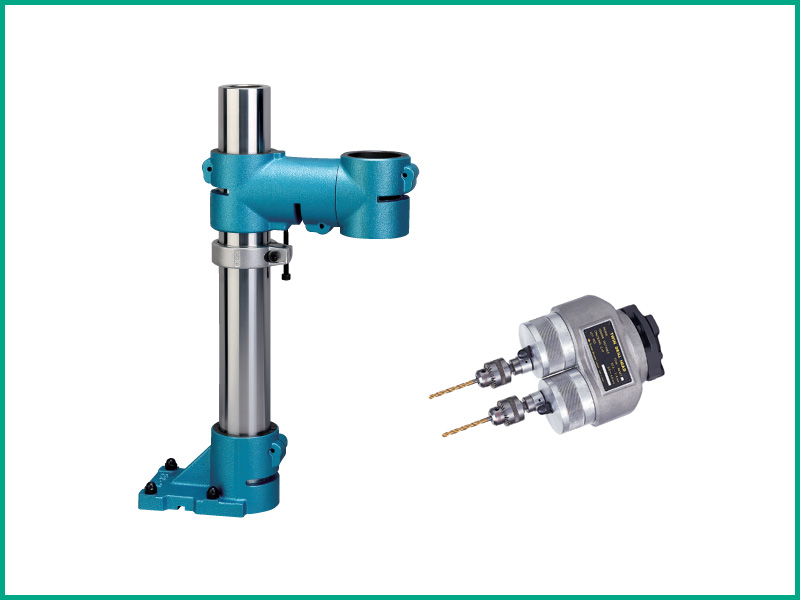

Accessories

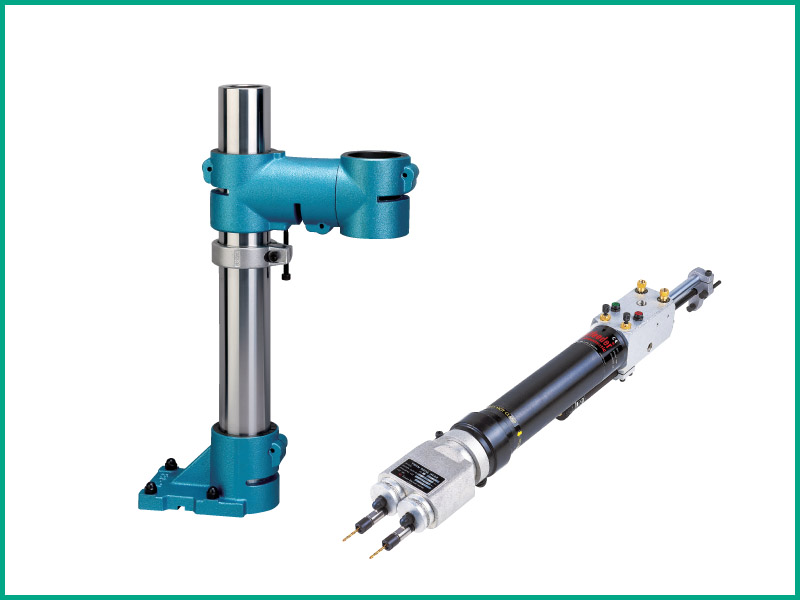

Gun Drilling machines

Gun Feeder

The "Gun Feeder" is a high-precision, high-efficiency gun drilling machine developed exclusively for small-diameter, deep holes. It is optimized for drilling small-diameter and deep holes used in applications like fuel injection nozzles, sleeve pins for molds, and parts for hydraulic machines.