Ream Roller Burnishing tool

Newly developed the reamer and roller burnishing combined tool that easily simultaneously provides the mirror finish in one operation. The rollers works as a guide to restrict vibration or run-out during the operation.

Example of use:

- connecting rods (smaller holes)

- piston holes

- hydraulic shock absorbers

- hydraulic and pneumatic cylinders

- accumulators, etc.

- piston holes

- hydraulic shock absorbers

- hydraulic and pneumatic cylinders

- accumulators, etc.

(1) High speed and high precision inner diameter finishing

- Available dimensions with tolerance H7 - H8

- Roughness Rz 0.8 μm and better

(2) Low cost

- Indexable reamer and roller tool

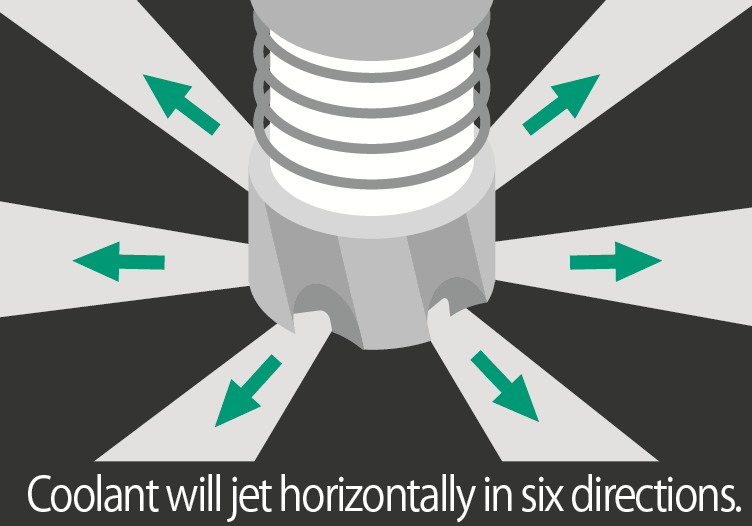

- Coolant-through realizes the long life time of consumable parts

(3) Quality improvement

- best finish with frictionless and high-sealing

- increasing of fatigue strength of the material

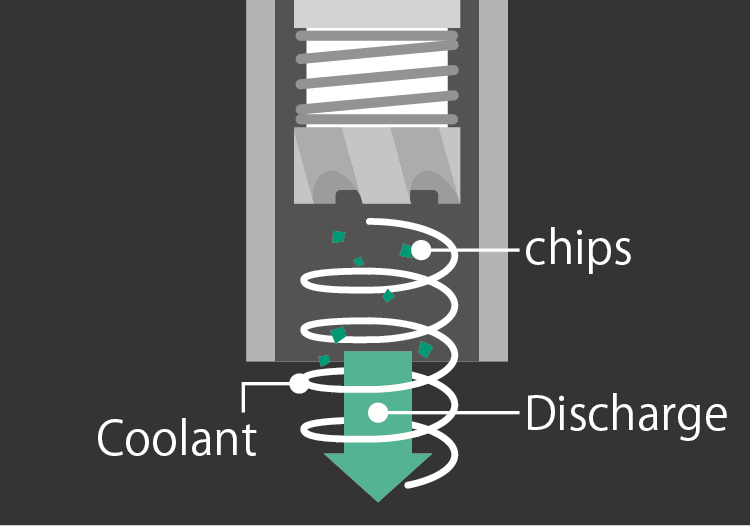

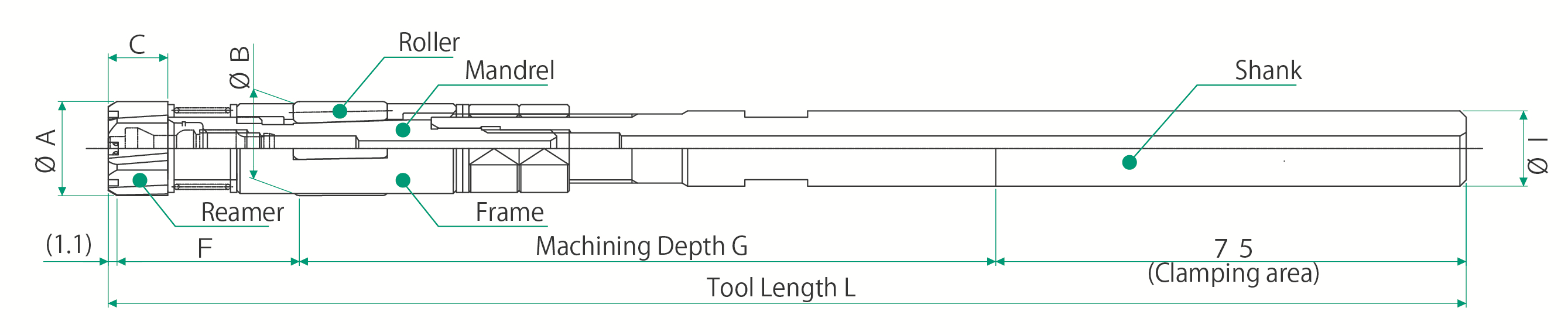

Mechanism

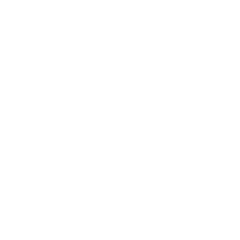

Roller Burnishing

- Rollers compress the metal to make smooth finish which is suitable for sliding or sealing surface.

- Compressed metal surface is strong against friction and/or fatigue stress.

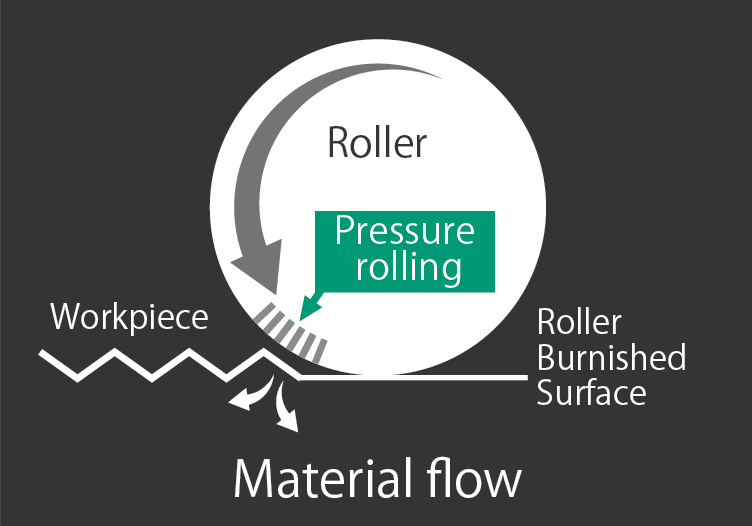

Roller Guide

- Roller works as guide to restrict vibration during operation, while obtaining stable dimension finish.

- The Roller, while compressing the metal surface, erases retractscratches made by the reamer.

Replaceable Reamer

- High Speed Cutting

- Throw-away Reamer reduces running cost

- Coolant-through specification

Chips discharging

- Left-helix Reamer and coolant-through flows out cutting chips in forward direction.

-

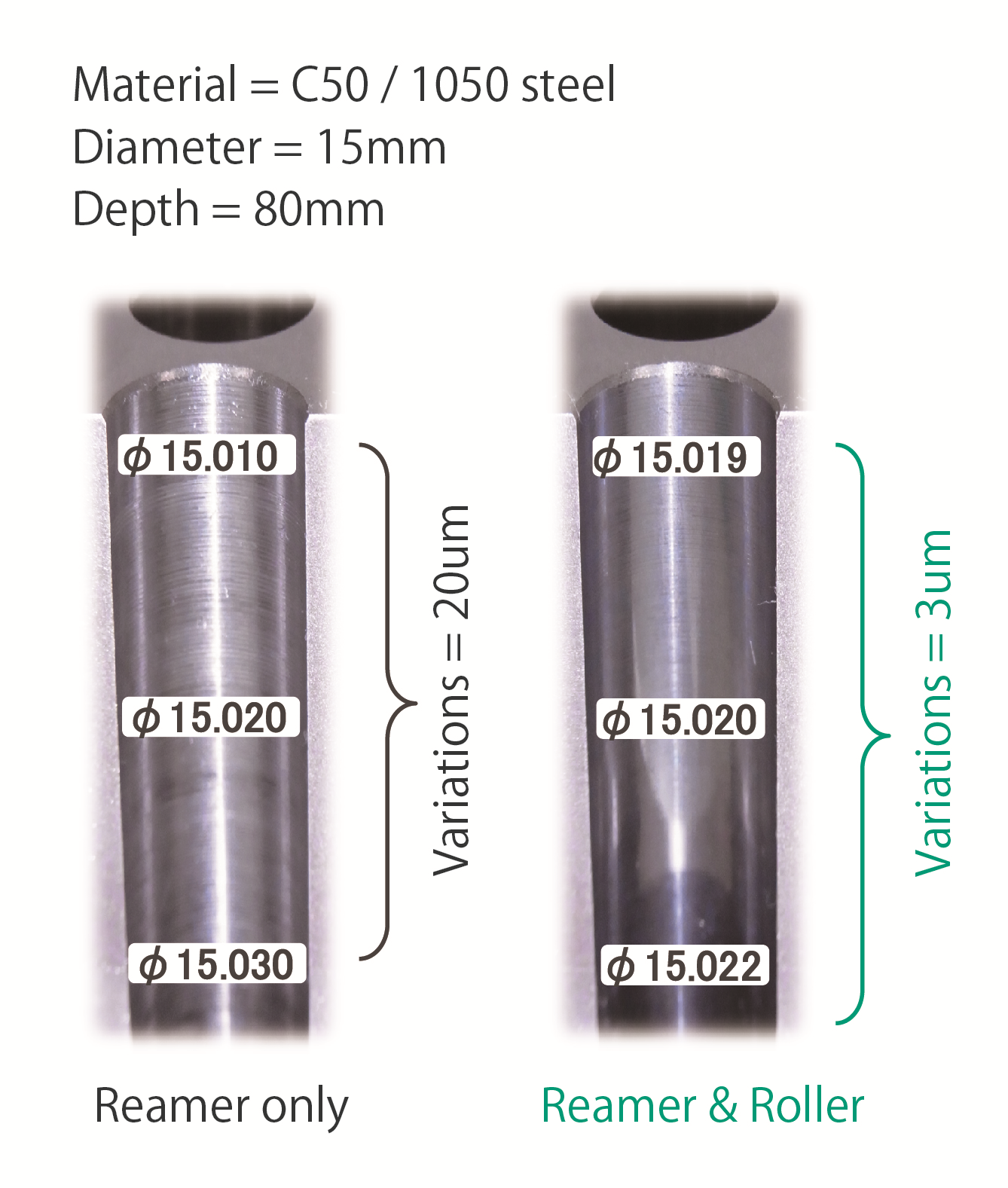

Machining Example

-

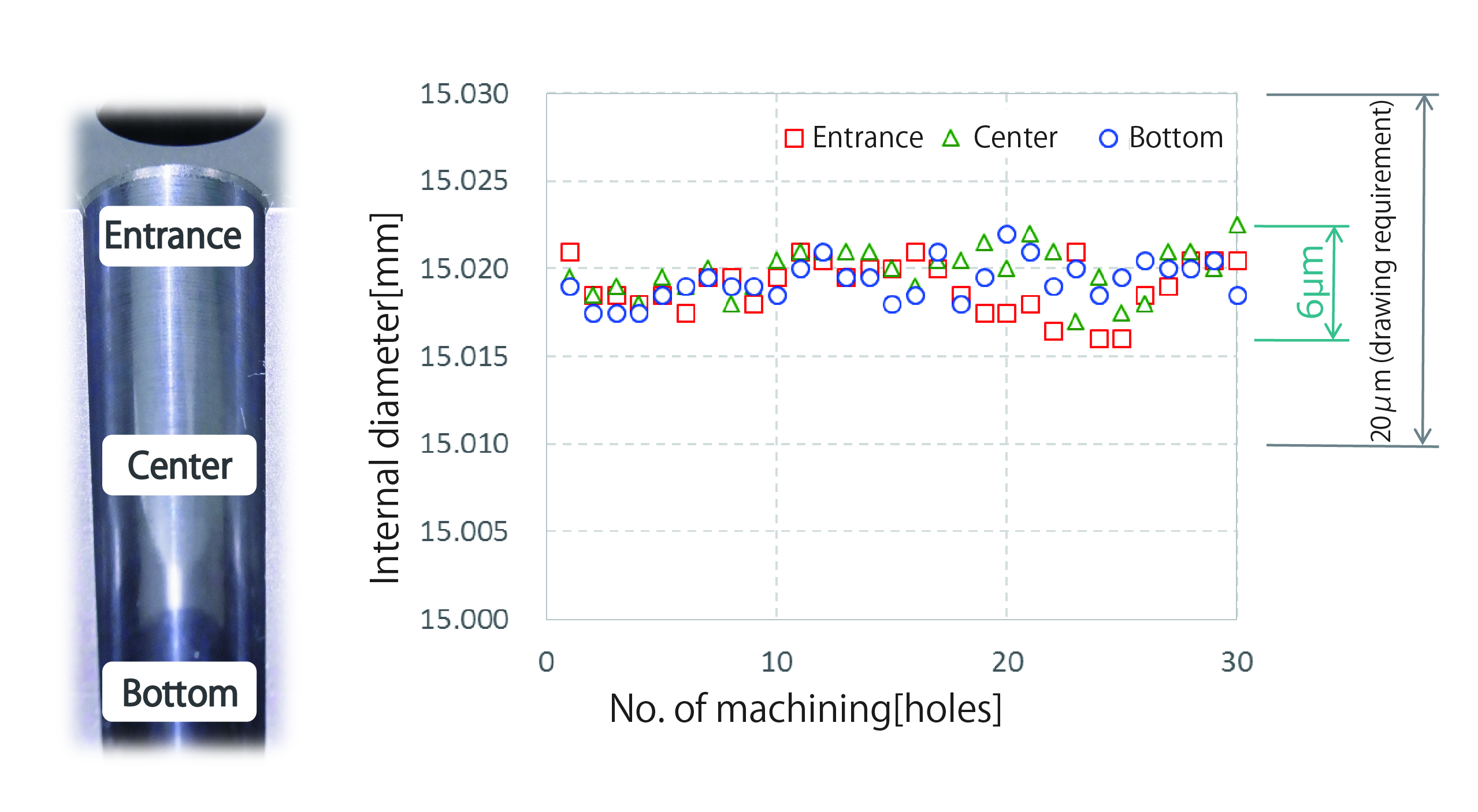

Sequent Machining Results

-

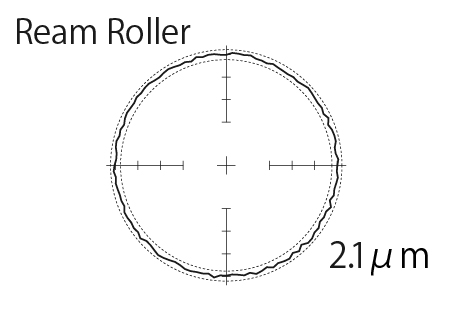

Roundness

-

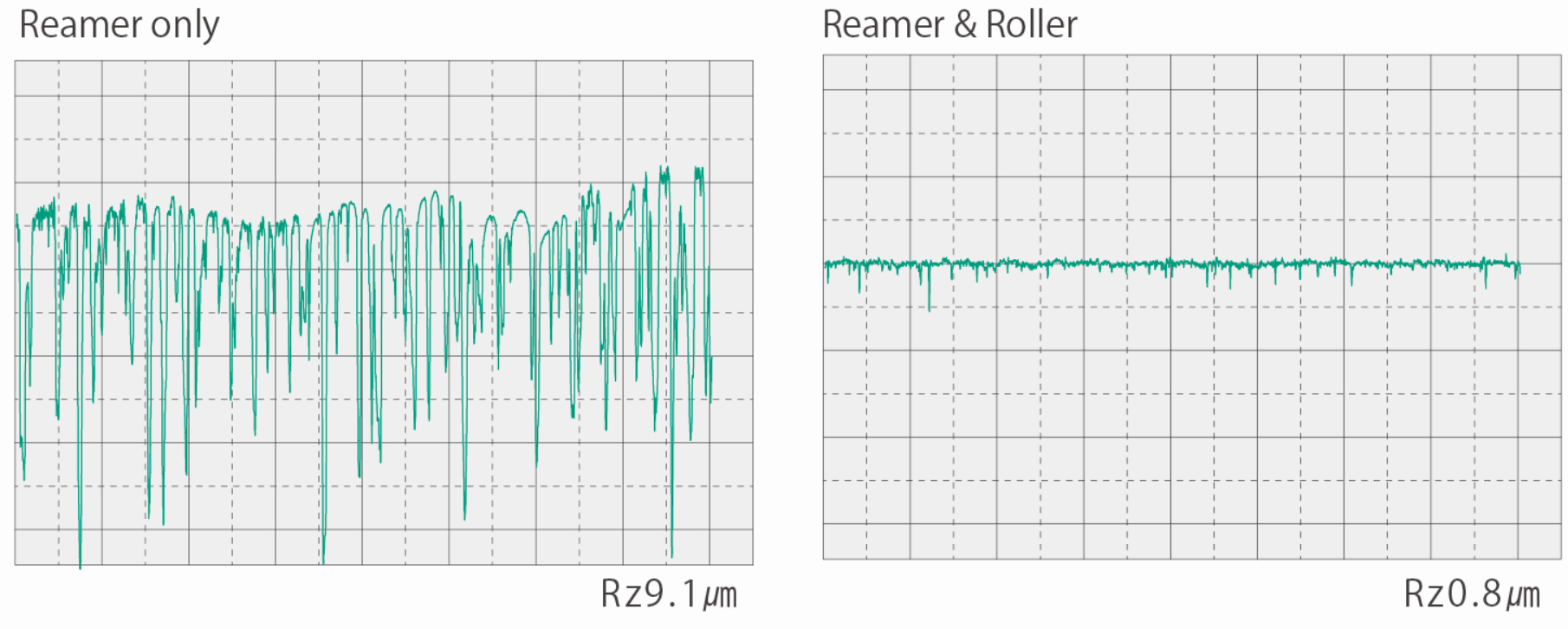

Roughness Comparison

-

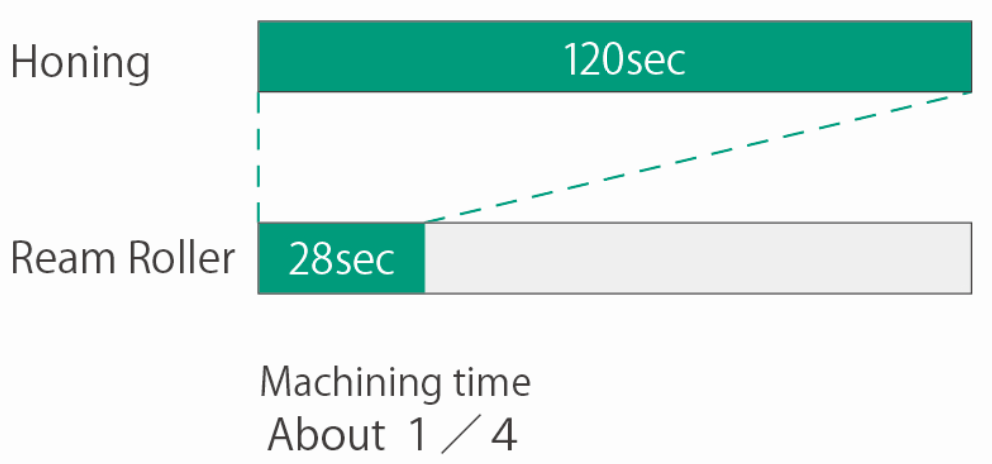

Operation Time Comparison

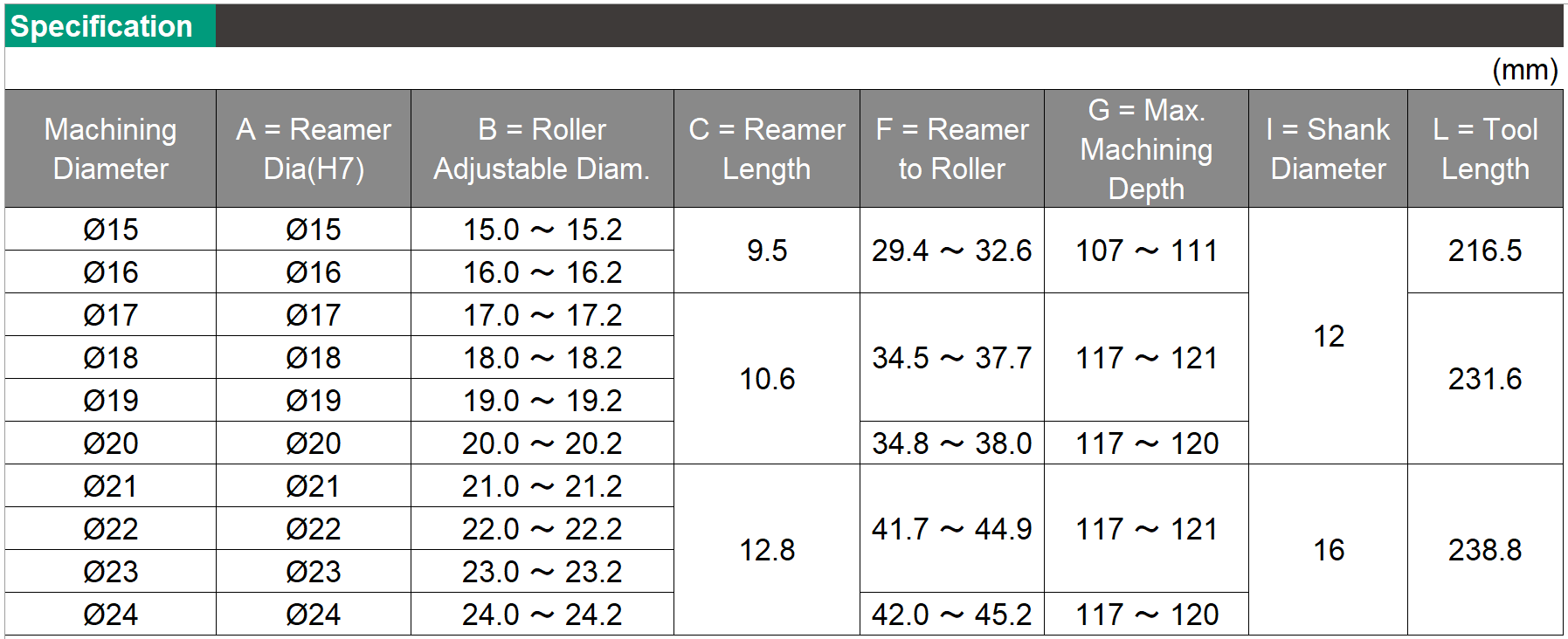

Dimensions (mm)

Obtained diameter is approx. 0.01mm larger than Reamer diameter.

A max. machining depth (G dimension) varies depending on roller diameter setting (B dimension).

Please feel free to contact us if you need the size which is not shown on above table.

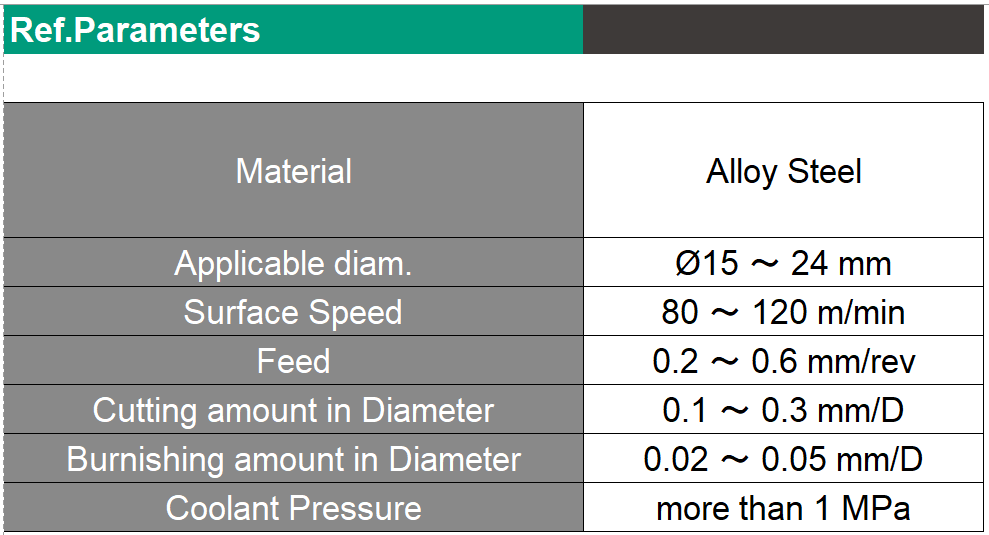

Please contact us for more machining references of other material.

Burnishing amount = (Roller diameter) - (Reamer Diameter)

The machine has to be equipped with coolant-through specification.