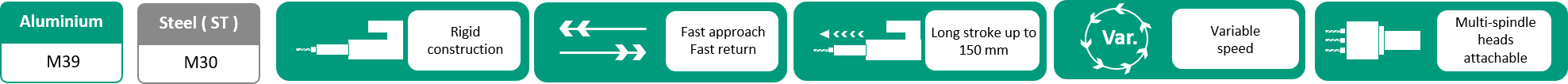

Servo operated tapping units REVO SSTR

The Synchro Tapper REVO SSTR series are units capable of high speed precised work. The spindle rotation speed can be adjusted by the speed control box and build-in AC Servo motor improves an accuracy and reduces a total cycle time. A Synchro Tapper units with a servo driver can be easily connected to customer's universal PLC.

Capacity

Notes:

1. Tapping capacities are for spiral tap or point tap (upper part) and for hand tap (lower part).

2. Rotation speed should be adjusted according to the material type, tapping diameter, tapping speed, etc.

3. Feed Gears will be delivered according to selected thread pitch.

4. Pitch Feed speed can be adjusted by speed control box.

5. Marking "B" is for using the feed servo motor with brake. It is used with vertical installation.

6. AL: Aluminum, ST: Cast Iron Steel, Wt: Weight

2. Rotation speed should be adjusted according to the material type, tapping diameter, tapping speed, etc.

3. Feed Gears will be delivered according to selected thread pitch.

4. Pitch Feed speed can be adjusted by speed control box.

5. Marking "B" is for using the feed servo motor with brake. It is used with vertical installation.

6. AL: Aluminum, ST: Cast Iron Steel, Wt: Weight

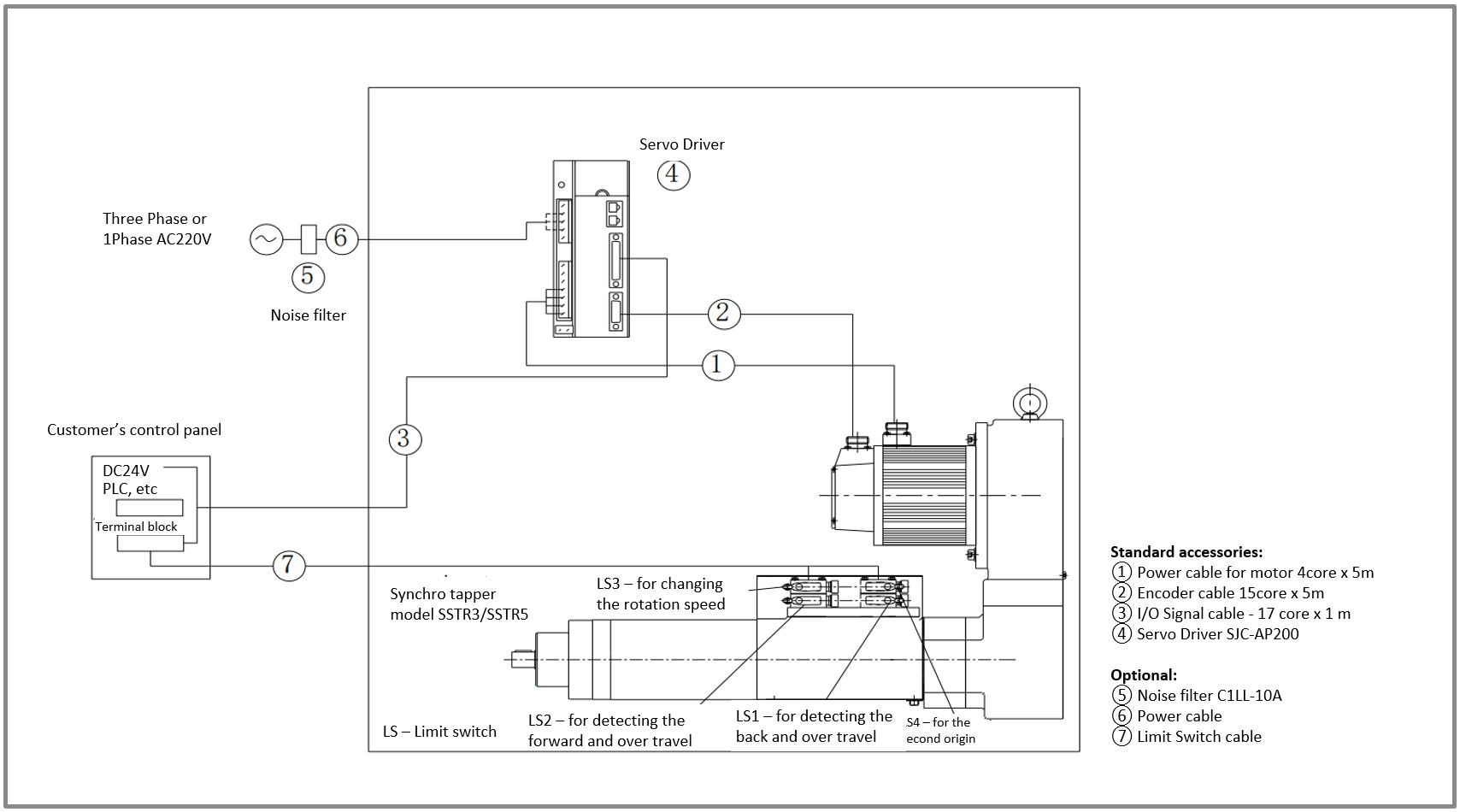

Electrical System Diagram for Synchro Tapper Revo SSTR3 and SSTR5

Electric parts 1. up to 5. are supplied as a standard.